- Standard 9 management cycles

This is the function of standard ERP package. Pronology currently owns an ERP system bought from Lancer in Taiwan. We use this system to control 9 standard operation cycles.

- Special customized management

Standard ERP packages should fit into different fields. For such special industry, we have to make some customized programs. Particularly, Pronology is in a low volume and high mix EMS filed. We need to accommodate ourselves to meet more requirements from different customers. Therefore, Pronology has a MIS design team to make many customized programs. Then, we can satisfy the documentation requirements from most of our customers.

- Bridge of MIS

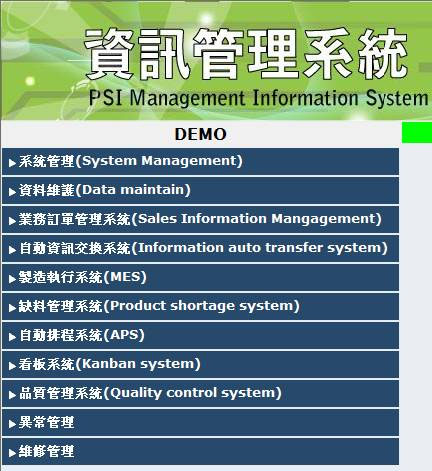

ERP system is a data information management system. Security and accuracy are extremely important. If there’s any error occurred, the corp. will get into a big trouble. Therefore, ERP system is not so flexible to make lots of changes. To solve the issue, we develop our own package, named MIS system. To automatically manage our information flow among customers, vendors and PSI internal teams. Information extracted from ERP system can be used more flexibly in our MIS system.

As mentioned in above ERP system, Pronology develops some control and communication systems as a bridge among customers, vendors and PSI internal teams. All of the developments will be finished by Q3’12. Described as below and see table 1 for the UI of MIS system.

- Bridge of Sales order

To do the business of low volume/ high mix, we get a lot of small orders from customers every day. We have many sales people to transfer the customer orders to our system. The cost is high and efficiency is low. Besides, people make mistakes sometimes. Therefore, we design an automatic sales order transfer system to transfer sales order to Pronology’s system automatically. Different customers use different excel format, Pronology develops a program to transfer the different format to be a standard one and enter ERP system promptly.

- Bridge of Technical information

Every electronic product has BOM, Gerber, XY-file, Test SOP, Assy SOP & Packing SOP… It’s not easy to handle all of the information and deliver the information to the right production line. Nowadays, most of customers request short lead time, but, EMS company doesn’t have too much time to forward the information from customer’s end to each production lines. We develop a system to transfer customer’s technical information to our file server automatically. Our target is to receive the information from customer and pass them to our production lines by half day.

- MES

To get the real time production status is necessary for a good management. To use standard MES package can’t fit our production flow and too much complex. We’ll develop a MES system by ourselves and both PSI and its customers can get the real time information from the new system.

- Shortage management system

To control the quantity and schedule of semi-products is always a major issue for a factory. Therefore, Pronology develop a shortage simulation system. We use this system to realize when each sales order can be finished, and if there is any excess working orders for different production lines.

- APS

To be a low volume/high mix manufacturer, Pronology receives several orders every day. In order to confirm the delivery schedule to customer in time, we plan the production schedule by daily bases. We always use half day to plan the schedule and re-schedule if material can’t arrive on time. It’s quite a nightmare when we have increasing customers these years. Eventually, we develop our own APS. So far, customer increasing and schedule change are not an issues any more. And we are able to plan our production schedule more flexibly and faster.

- Kanban system

Pronology will develop unique Kanban system to use tablet PC as a tool. All of our production lines will use tablet PC and the staff can check all of the production information from it. Information covers production information of all of the working orders, real time production information and all the SOPs.

- Quality control system

Quality system of Pronology covers all of the SOPs of ISO system and daily, weekly, monthly quality data. We’ll accumulate the QA information in our MIS system. All the people can review the information in the system to prevent the gaps between different teams.

It’s an amazing year for Pronology in 2012. We’ll finalize our two major management systems and we are confident that all the information among customer, vendor and PSI will be in real time and transparent. Surely, it’s another definition of “ Your trust, Our survival”.